A brief history of the township of Bradford, Manchester

An early reference to Bradford is in 1196 when it was recorded as ‘Bradeford’, meaning a ‘broad ford’. The name was derived from a crossing place somewhere on the river Medlock.

Later, for administrative purposes, Bradford became part of the Salford Hundred in the County Palatine of Lancashire.

The township is bounded by Beswick, Holt Town, Miles Platting, Clayton and Openshaw and the river Medlock and Ashton Canal pass through it.

Up to the commencement of the Industrial Revolution, Bradford was rural with woodland, pastures and streams.

It is reported that wolves and eagles once inhabited the woodlands and that honey production was part of the local economy.

National Coal Board Report (NoteExtract from this report, dated about Sep 1959, concerning the progress of industrial relations with the growth of Bradford Colliery.)

Coal mining at Bradford Colliery can be traced back to c.1590 and in the reign of James I (1603-1625) it had an annual output of around 10,000 tons and was probably supplying the entire needs of Manchester (NoteIn 1610 there were coal mines at Bradford, near Manchester, (Local Notes and Queries, Manchester Guardian, No. 173.). With the rapid expansion of the Manchester during the Industrial Revolution,

the Manor of Bradford was unable to meet the demand and coal had to be brought in from mines such as those at Clayton, Moston, Worsley and Clifton.

Clayton and Moston collieries in Manchester were in close proximity to Bradford Colliery to the south and north, respectively. Clayton Colliery was about 558 yards distant and eventually it merged with it.

Moston Colliery was about 2.4 miles distant and after nationalisation in 1947 a horizon tunnel was provided to connect it to Bradford Colliery.

At first, coal was mined at shallow depths, but even so, the capital required was beyond the means of all but the wealthy and it was recorded during Tudor days that several hundred pounds had been invested at a colliery in Bradford Manor, where one of the shafts was sixty-seven feet deep.

A document, dated 21st Oct 1740, shows that Sir Oswald Mosley leased to John Seddon, of Manchester, '···· the mine and mines, vein and veins, seam and beds of coal kannel (NoteKannel (or Cannel) is a bituminous coal that burns brightly with much smoke. Cannel coal is a dialectal variant of candle coal from its bright flame.) to be found in the land around Bradford ····'. In return, Seddon agreed to pay Sir Oswald Mosley the sum of £50 per annum for such coal as was raised by ten 'gotters' (Note'Gotters were Hewers of Coal, that is, Coal Miners.).

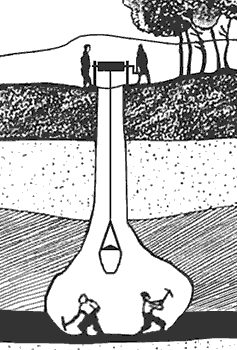

Historical accounts for c.1590 document several burials of miners killed at ‘Bradford Colepitte’. At this time workings were shallow and coal was extracted from thin seams. This practice continued into the 19th century but it is known that coal was being wound in shafts from 1845 onwards. These early coal mines were known as bell pits and in practice a shaft was sunk to reach the seam where coal could be excavated by miners. A winch was used to raise the coal to the surface in a basket in the manner of raising water from a well. As coal extraction proceeded the bottom of the shaft was enlarged and a sloping roof was created as the coal and surrounding rock was removed. Thus these mines were called ‘bell pits’ because in cross section they resembled a bell. Miners, often women and children, were lowered into (or raised from) a bell pit in the basket used to raise coal by clinging onto the rope. When a pit was considered to be too dangerous to work any further it was abandoned and another shaft was sunk close by. The abandoned pit was then backfilled using waste material taken from the new pit.

Section of a bell pit.

It is evident that Bradford supplied all the colliery's manpower until 1870. In that year Edward Bryan (NoteEdward Bryan was killed in a mine accident in 1874.) and his six sons arrived from Pendleton to work at the colliery and it is at this time we have the first evidence of a strike, since the local miners '···· were so suspicious of these strangers that they did not go down the pit until they had had a good look at them'. The Bryans remained and became 'gradely Bradford folk' themselves in good time.

When the Lancashire Miners' Federation came into being on the 19 Apr 1881, its first Secretary was a Bradford Colliery man, Thomas Seddon, who was also elected Secretary of the Miners Federation of Great Britain, from its inception in 1889 until 1910.

Many Bradford miners made names for themselves in wider spheres. One of the Miners' Federation representatives returned to the House of Commons in the 1910 General Election, was John Edward Sutton (23 Dec 1862-29 Nov 1945), a Checkweighman at the Colliery (NoteCheckweighmen were elected and paid by the men to ensure fair payment for coal won and they worked alongside the employer's wage clerks.). He was the Member of Parliament for the Manchester East Constituency from Jan 1910 until 1918 when the constituency was abolished. He was a trade unionist and Labour politician. He joined Bradford Colliery, aged 14 years, where he became a Checkweighman as well as becoming Secretary of the Bradford Branch of the Lancashire and Cheshire Miners' Federation. In 1894 he was elected to Manchester City Council as an Independent Labour Party Councillor for the Bradford Ward. The Lancashire and Cheshire Miners' Federation was founded in 1897 and it was wound up in 1945. Its office was in Bolton.

Typical of many families, who served Bradford Colliery during its relatively slow growth until the end of World War II, was John Bryan, a Checkweighman and Secretary of the Bradford Branch of the National Union of Mineworkers (NUM). A grandson of the Edward Bryan of the 1870 intruders, John Bryan was a loyal supporter of the NUM who was liked and respected by both management and men.

The labour force supplying Bradford Colliery up to World War II was mainly drawn from descendants of the pioneer miners and their progress in social and political affairs followed a pattern that was typical of coal mining communities throughout Britain.

In 1871 it was recorded that R T Parker was then the owner of Bradford Colliery while the occupiers, for rating purposes, were Clegg and Thomas Livesey. The table below provides some details of Bradford Colliery between 1880 and 1945. Additionally, trade directories list the following names: Thomas Porter, coal owner (1828/29); John Brown, agent (1841); Charles James Stanley Walker (1841); Clegg and Thomas Livesey Jr, coal owners (1895); Henry Shaw (1903); G H Pybus, Henry Shaw and F L Ward (1909 and 1911). Regarding Thomas Porter, it is understood that he showed unfairness to his miners and this may be the reason for industrial unrest that prompted a strike in 1844.

| Year | Mine Shaft | Manager | Under-Manager | Men Below Ground | Men Above Ground |

|---|---|---|---|---|---|

| 1880 | Deep¹ | Edward Williams | |||

| 1896 | Deep | H L Wood | George Bentley | 404 | 125 |

| 1908 | Deep | George Bentley | James Parkinson | 644 | 146 |

| Parker² | Chris Nurney | 388 | 53 | ||

| 1918 | Deep | T H Dixon | J Garner | 675 | 113 |

| Parker | M Lomas | 498 | 122 | ||

| 1923 | Deep | F H Fisher | T F Radford | 745 | 186 |

| Parker | M Lomas | 284 | |||

| 1945 | J F Carr | R Mullin | 642 | 218 |

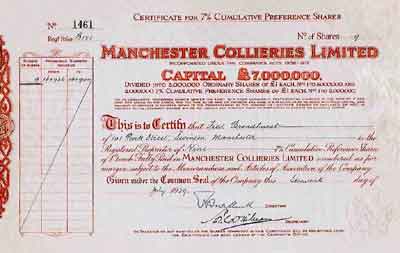

The names of the proprietors of Bradford Colliery during Victorian times are elusive. Descendants of the Livesey family recorded on the 1841 Census became proprietors and it was known as the Bradford Colliery Co. In 1899 it was acquired by the 'Fine Cotton Spinners and Doublers Association' who considered that they should own a colliery that supplied them with the coal used to power their mills. During this period of ownership the mine retained its Bradford Colliery Co name. At this time, the Parker and Crombouke Mines (seams) were being worked. The 'Fine Cotton Spinners' were aware of the existence of the rich Roger Mine but as they knew nothing about coal mining and had insufficient resources, they were unable to mine it. In 1935 the 'Fine Cotton Spinners' sold out to Manchester Collieries Ltd who had both the resources and mining knowledge to work the Roger Mine.

The Livesey surname occurs again in records for 1896/97 when Clegg Livesey and Thomas Livesey Jr, along with Richard Johnson and F L Ward of Bradford Colliery, are mentioned as members of the Federated Institute of Mining Engineers.

The last self-governing operating company was Bradford Colliery Company Ltd but in 1935 this company amalgamated with Manchester Collieries Ltd. Bradford Colliery was then controlled by Manchester Collieries Ltd between 1935 and 1947 when it was nationalised. After nationalisation, the seeds of reorganisation were sown by the deepening of Parker Shaft (No. 2) to the 900-yard level of Deep Pit Shaft (No. 1). When it was nationalised, Bradford Colliery came under the control of the National Coal Board (NCB). Vesting day was on the 1 Jan 1947. A plan of the Roger Mine workings dated 27 May 1954 and deposited at the NCB Mining Records Office on the 28 Aug 1969 records that the No. 1 shaft was then 923.25 yards deep and the No. 2 shaft was then 955.81 yards deep.

E TENEBRIS LUX.

'Light out of Darkness'

Archive References

Lancashire Archives Ref. QSP/2591/9 dated c.1810. Manchester. Instructions for motion that appeal [of Messrs. Chadwick Tipping and Co., proprietors of Bradford Colliery, against rating assessment] be struck out.

Title deeds relating to Bradford Colliery. Manchester Cathedral Archives Ref. Mancath/2/A/1/Newt/16/7 dated 1829-20th century. Includes leases of mining rights to Bradford Colliery and 999 year leases of land for building upon to William Hutchinson.

As stated above, the operating company was first known as Bradford Colliery Co and this was extant by 1866 when Thomas Livesey Sr (c.1800-4 Aug 1878) stepped down as a partner to leave Richard Johnson and Clegg Livesey as business partners. Subsequently the Bradford Colliery Co Ltd was incorporated and this was wound up on the 12 Apr 1939 as a result of the colliery having been acquired by Manchester Collieries Ltd in 1935.

Manchester Collieries Ltd

This company was incorporated in 1929, Company No. 237654, and its Registered Office was at Walken. Its sales office was at Arkwright House, Parsonage Gardens, Manchester.

The Managing Director and Chief Mining Engineer was James Tardif Browne FGS and the District Mine Managers were Sir Humphrey Browne CBE and John Brass Jr.

Following nationalisation of the coal-mining industry on the 1 Jan 1947, Sir Humphrey Browne was appointed as the Director General of Production for the National Coal Board and later he was appointed Chairman of the Divisional Board of the West Midlands Division and then Deputy Chairman of the National Coal Board.

Manchester Collieries Ltd was formed from a consortium of independent colliery companies working the Manchester Coalfield:

Astley & Tyldesley Collieries Co Ltd. Atherton Collieries. Bridgewater Estates Ltd and its associates, Bridgewater Collieries Ltd and Bridgewater Wharves Ltd. Clifton & Kersley Coal Co Ltd and its associates, Pilkington Colliery Co Ltd, Outwood Collieries Ltd and Collieries (Clifton & Kersley) Ltd. Fletcher Burrows & Co Ltd. Andrew Knowles & Sons Ltd and its associate, Andrew Knowles Wharves Ltd. William Ramsden & Sons. John Speakman & Sons Ltd, owners of Bedford Colliery at Leigh.

Collieries acquired by Manchester Collieries Ltd

Site location latitude & longitude in brackets:

, off the the south side of Agecroft Rd, Pendlebury, (53.50999, -2.30333).

Astley Green Colliery, Higher Green Ln, Astley, (53.49427, -2.44552)

Bedford Colliery, off the west side of Green Ln, Leigh, (53.50389, -2.49612).

Bradford Colliery, Forge Ln, Bradford, Manchester, (53.48266, -2.19691).

Brackley Colliery, between Salford Rd and Plodder Ln, Little Hulton, (53.54048, -2.43964).

Chanters Colliery

, off the the south side of Agecroft Rd, Pendlebury, (53.50999, -2.30333).

Astley Green Colliery, Higher Green Ln, Astley, (53.49427, -2.44552)

Bedford Colliery, off the west side of Green Ln, Leigh, (53.50389, -2.49612).

Bradford Colliery, Forge Ln, Bradford, Manchester, (53.48266, -2.19691).

Brackley Colliery, between Salford Rd and Plodder Ln, Little Hulton, (53.54048, -2.43964).

Chanters Colliery (Atherton Collieries), Nos 1 & 2 Pits, off the east side of Tyldesley Old Rd, Hindsford, Atherton, (53.51950, -2.47976).

Gibfield Pit

(Atherton Collieries), Nos 1 & 2 Pits, off the east side of Tyldesley Old Rd, Hindsford, Atherton, (53.51950, -2.47976).

Gibfield Pit (Atherton Collieries), Coal Pit Ln, Atherton, (53.52711, -2.50583).

Gin Pit

(Atherton Collieries), Coal Pit Ln, Atherton, (53.52711, -2.50583).

Gin Pit , off the south side of Ley Rd, Astley, (53.50627, -2.46901).

Howe Bridge Colliery (Atherton Collieries), embraced a number of pits, including Crombouke & Victoria Pits, off the west side of Leigh Rd, Howe Bridge, Atherton, (53.51569, -2.51293).

Mosley Common Colliery

, off the south side of Ley Rd, Astley, (53.50627, -2.46901).

Howe Bridge Colliery (Atherton Collieries), embraced a number of pits, including Crombouke & Victoria Pits, off the west side of Leigh Rd, Howe Bridge, Atherton, (53.51569, -2.51293).

Mosley Common Colliery , Nos 1 to 5 Pits, off the south side of Bridgewater Rd, nr Boothstown, (53.50984, -2.41615).

Newtown Colliery

, Nos 1 to 5 Pits, off the south side of Bridgewater Rd, nr Boothstown, (53.50984, -2.41615).

Newtown Colliery , off the east side of Bolton Rd, Clifton, (53.52112, -2.33389).

Kermishaw Nook Pit

, off the east side of Bolton Rd, Clifton, (53.52112, -2.33389).

Kermishaw Nook Pit , at the intersection of North and South (Coal Pit) Lanes, Astley, (53.50198, -2.47208).

Outwood Colliery, off the north side of Ringley Rd West, Radcliffe, (53.54958, -2.33854).

Pendleton Colliery

, at the intersection of North and South (Coal Pit) Lanes, Astley, (53.50198, -2.47208).

Outwood Colliery, off the north side of Ringley Rd West, Radcliffe, (53.54958, -2.33854).

Pendleton Colliery , off the west side of Whit Ln (now Langley Rd South), Pendleton, (53.50179, -2.28935).

Sandhole Colliery

, off the west side of Whit Ln (now Langley Rd South), Pendleton, (53.50179, -2.28935).

Sandhole Colliery (Bridgewater Colliery), off the east side of Old Clough Ln, Worsley, (Ellesmere Golf Club), (53.51770, -2.37473).

Shakerley Colliery (Nelson & Wellington Pits). The two pits were about 775 yards apart. Nelson Pit was off the east side of Shakerley Ln (now Lancaster Ave),

Tyldesley (53.52269 -2.46362) while Wellington Pit was off the east side of Common Ln, Tyldesley (53.51762 -2.45710, bearing SE 142°). Both pits were previously worked by William Ramsden & Sons.

St George's Bank Colliery, off the west side of Astley St, Tyldesley, (53.51171, -2.47133).

Wheatsheaf Colliery (Pendlebury Colliery), off the east side of Bolton Rd, Pendlebury, (53.51471, -2.32391).

Walkden Yard, off the south side of Manchester Rd East, Little Hulton, Walkden, (53.52251, -2.40339). This yard contained workshops for engineering and maintenance support.

(Bridgewater Colliery), off the east side of Old Clough Ln, Worsley, (Ellesmere Golf Club), (53.51770, -2.37473).

Shakerley Colliery (Nelson & Wellington Pits). The two pits were about 775 yards apart. Nelson Pit was off the east side of Shakerley Ln (now Lancaster Ave),

Tyldesley (53.52269 -2.46362) while Wellington Pit was off the east side of Common Ln, Tyldesley (53.51762 -2.45710, bearing SE 142°). Both pits were previously worked by William Ramsden & Sons.

St George's Bank Colliery, off the west side of Astley St, Tyldesley, (53.51171, -2.47133).

Wheatsheaf Colliery (Pendlebury Colliery), off the east side of Bolton Rd, Pendlebury, (53.51471, -2.32391).

Walkden Yard, off the south side of Manchester Rd East, Little Hulton, Walkden, (53.52251, -2.40339). This yard contained workshops for engineering and maintenance support.

Bridgewater Offices of Manchester Collieries Ltd on Bridgewater Rd, Walkden. Formerly the offices of Bridgewater Collieries Ltd and afterwards the headquarters of the North West Region of the National Coal Board. The building was demolished in 1976. The clocktower was added in 1900 and the clock was known as the Lady Bourke clock after Lady Ethel K J Bourke.

Manchester Collieries Ltd commenced voluntary liquidation proceedings in 1954 and these were completed at a general meeting held on the 12 Jul 1956.

A Profile of Bradford Colliery (NotePublished by the Western Area Public Relations Department of the National Coal Board and dated about Sep 1968.)

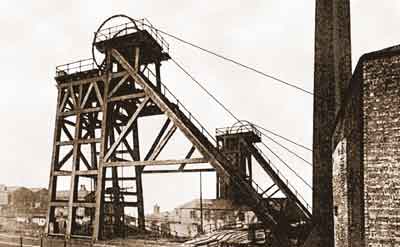

The first modern shaft at Bradford Colliery was sunk in 1854 and this was Deep Pit Shaft (No. 1) and it was reputed to be the second deepest in British coalfields.

A second shaft was sunk in 1902 and this was Parker Shaft (No. 2) (NoteThe two shafts initially had wooden headgear, which was later replaced by more modern steel headgear.).

This event was reported in the Manchester Evening News on the 23 Oct 1902. At this time the colliery was owned by the Fine Cotton Spinners and Doublers Association and the managing director was A H Dixon.

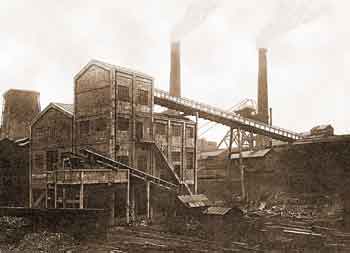

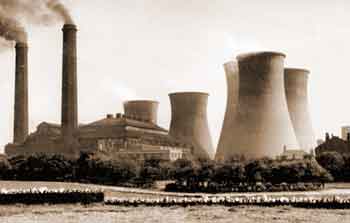

Bradford Colliery, 1910.

Reorganisation and reconstruction of the Bradford Colliery was completed in 1958 when four faces were in operation in two seams; three faces in the 6-feet thick Roger Mine and one face in the 3 feet 8 inch-thick Crombouke Mine which was 26 yards above the Roger Mine. The two shafts, now both 900-yards deep, had insets at 730 yards. From each of these level horizons were driven, one pair in a northerly direction below Newton Heath and into the Moston area and the other pair westerly below Holt Town and Ancoats .

Shaft No. 1 served as a 'downcast' to carry air down into the colliery and this was equipped with a cage for winding men and supplies. Shaft No. 2, fitted with a Koepe-winder installation, was the 'upcast', which extracted stale air (NoteThe new concrete winding tower and associated buildings for shaft No. 2 were developed and built by A Monk & Co Ltd of Warrington at a cost of £1,048,891. The concrete tower was known as a Koepe Tower and Winder and this was installed in 1954. It used an endless rope to which two skips, each of 12-ton coal capacity, were fixed, instead of two ropes coiled over a drum.). The winding time from the 900-yard level was 97 seconds (NoteA speed of 19 miles per hour.), the capacity of the shaft being up to 400 tons per hour.

The seams lay in a gradient of 1 in 1½ (33.7° slope) to 1 in 2½ (21.8° slope) and were worked so that roadways (horizons) were level. Every face was fully mechanised, coal being won by a 150hp BJD Anderton shearer, cutting a 30-inch wide slice of coal on its run from the lower level main gate to the higher level tail gate. On the return journey it ploughed the coal into the face conveyor. The faces were supported by hydraulic props and link bars.

Horizon coal mining

This is a method of mining suitable for inclined coal seams. Horizons (also known as insets) are, in essence, underground roadways driven as level as possible independently of the gradient of the seams.

The vertical distance between horizons was variable, depending upon the seams available and their gradient. Connections between horizons were made by means of in-between shafts.

The colliery had long been connected to the adjacent CEGB (NoteCentral Electricity Generating Board. The CEGB was responsible for electrical generation, transmission and bulk sale of electricity from 1958 until the 1990s.) coal-fired power station in Stuart St by means of a tunnel containing a conveyor belt to transport coal directly to the boilers. This 500-yard long tunnel passed below Mill St and the Ashton Canal.

Stuart St Power Station, with St Paul’s Church on the right, viewed from Mill St, 1962. The power station was commissioned in 1900 and it closed in 1975 to be demolished shortly afterwards. St Paul’s Church opened in 1908 and was demolished in 1970.

In addition to the tunnel to the power station two horizon tunnels were provided, one connecting to Ashton Moss Colliery (about 3.1 miles distant) and the other to Moston Colliery (about 2.4 miles distant). The purpose of these was to enable coal from both collieries to be transported to Bradford Colliery for washing and grading.

Although about £8M was spent on the colliery after nationalisation, its life was cut short, due to subsidence, and in Sep 1968 Bradford Colliery closed (NoteOn Friday, 6 Sep 1968.). In its last year the colliery produced 538,808 saleable tons of coal at an overall productivity rate of 31.8 cwt per manshift. At the time it was employing 1,556 men and about half of these were found jobs in neighbouring pits or other areas.

Bradford Tithe Map, 1845.

Coal Seams, known as Mines

The cluster of productive mines (seams) known as the Bradford Group includes the Bradford Four Feet, Charlotte, Doctor, Foxholes, Mary, New, Openshaw, Three Quarters Coal, Two Feet and Yard.

The Openshaw Mine, consisting of fireclay, is situated above the Charlotte Mine and it was used to manufacture firebricks.

Situated at a depth of about 509 yards the Bradford Four Feet Mine is the deepest and thickest of these seams. Below the Bradford Group are the Parker Mine, Crombouke Mine* and Roger Mine.

The insets to the Parker and Roger Mines are at depths of about 543 yards and 946 yards respectively and the Crombouke Mine is 26 yards above the Roger Mine.

As well as these, there are a number of unnamed thin coal seams.

Shafts (aka Pits)

Four shafts were sunk at Bradford Colliery over the years. The two earliest were Forge Pit and Little Pit, the latter being an air shaft used to ventilate the workings.

The first modern shaft was Deep Pit (No 1) which was sunk in 1854 and had a diameter of 18 feet.

This was also known as Livesey’s New Shaft. The second modern shaft was the Parker Shaft (No. 2) which was sunk in 1902. The two modern shafts were side-by-side with the Parker Shaft being the northernmost.

In 1953/54, the headgear of the Parker Shaft was replaced with a Koepe-winder installation. National Archive Ref. COAL 80/1806/43.

Forge Pit is believed to be the first deep shaft and this was sunk to a depth of more than 500 yards to reach the Bradford Four Feet Mine. This shaft was oval in section with the width across the widest part being about 9 feet. Miners were lowered down the shaft by a rope attached to a manually operated winch. At this time, it is likely that coal was transported from the coal face to the shaft in corfes, which were wicker-work baskets. These would then be hauled up the shaft using the same winch and rope.

Postscript

Although Bradford Colliery closed in 1968, it was not until 1973 that major demolition work started on the site. The steel headgear of No. 1 shaft was dismantled and in contrast the

relatively new concrete Koepe tower and winder of No. 2 shaft were blown up.

Even though there were still substantial reserves of coal, expansion of the underground workings was causing subsidence, particularly in the areas of Ancoats, Bradford, Cheetham, Collyhurst, Harpurhey, Miles Platting, Newton Heath, Openshaw and West Gorton. Accordingly, the London Gazette records that from the 5 Oct 1965 the NCB would require planning permission from Manchester City Council to expand the workings of the Crombouke, Foxholes, Mary and Roger Mines. Essentially, this meant that the NCB was left with no alternative but to close Bradford Colliery.

| Date | Name & Details |

|---|---|

| 21 Nov 1622 | Ffrancis Taylior of Bradford killed with a fall to ## coale pitte, was buried at Manchester Collegiate Church (Manchester Cathedral). |

| 16 Jan 1661 or 1662 | Thos. son to John Hilton slaine at Bradford coal pitt. |

| 10 Nov 1664 | Thos. Greene slaine at Bradford coal pitt. |

For more details about Bradford Colliery use the following menu:

Lancashire Mining Museum at Astley Green

The last surviving headgear and winding house in the Lancashire Coalfield.

| Bradford Colliery, 1926. Deep Shaft (No. 1) is on the right and this was the ‘downcast’ shaft sunk in 1854 and Parker Shaft (No. 2) is on the left and this was the ‘upcast’ shaft sunk in 1902. | |

|

|

| Bradford Colliery, 1928. | Bradford Colliery looking east, c.1935. Deep Shaft (No. 1) is on the right and Parker Shaft (No. 2) is on the left behind the building. On the left is Avonside 0-4-0 saddle-tank locomotive 'Bradford' used to shunt coal waggons across Forge Ln to the sidings behind the viewpoint and in the foreground is a Foden steam waggon. One of the coal waggons is marked ‘James A Fleet’ who was a local coal merchant. In 1939 James Arthur Fleet was resident on North Rd, Clayton. |

|

|

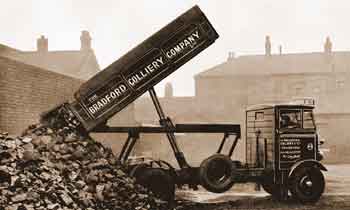

| A high tipping coal delivery lorry being loaded with coal from a hopper, 1920s. | A high tipping coal delivery lorry, 1920s. These lorries incorporated a special sub-frame that raised the body hydraulically to allow tipping over obstacles. They were made by Bromilow and Edwards Ltd of Bolton, Lancashire. This company was founded in 1919 and in 1969 it became Edbro (Holdings) Ltd. |

|

Mine rescue team, 1920s. |

|

|

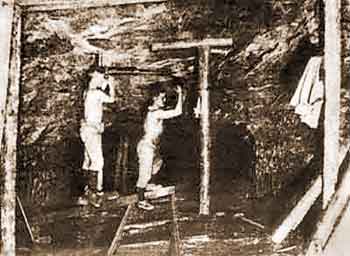

| Miners drilling coal. Note the rails used for the removal of coal. | A miner hewing coal. Note the timber pit props and lintels supporting the roof. |

|

|

| Bradford Colliery horizon junction, 1960. Two motorised trains are hauling tubs from the coal face to the shaft bottom where they will be brought to the surface. The one on the left waits while the one on the right passes by. The 95hp locomotives used to haul the 3-ton capacity tubs are battery operated. | Stuart St Power Station viewed from Philips Park, 1960s. A tunnel from Bradford Colliery containing a conveyor belt transported coal directly to the power station boilers. |

|

Avonside 0-4-0 saddle-tank locomotive, Bradford, at Robin Hood Sidings, Clifton, 1957. This locomotive was manufactured by the Avonside Engine Company of Avon Street, St Phillips, Bristol. |

Bradford Colliery Memorial Sculpture

This sculpture celebrates the lives of the coal miners who worked at Bradford Colliery and it was installed near Manchester City Football Club's Etihad Stadium that

adjoins the site of the colliery.