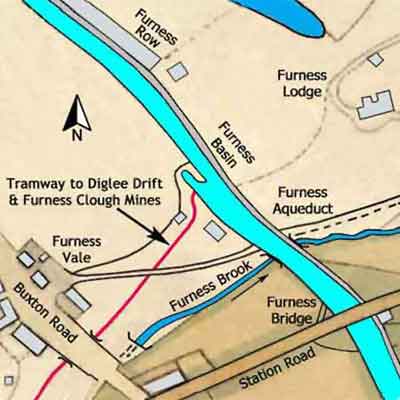

Furness Basin is situated on the offside of the canal in Furness Vale adjacent to Furness Aqueduct.

Furness Basin

Upper Peak Forest Canal

Grid Ref: SK 007 836

Tithe Map: 1851, Ref: EDT 137/2

Courtesy: Cheshire Archives & Local Studies

Diglee Drift Mine and Furness Clough Colliery were situated a short distance to the west of the village of Furness Vale, which was then in the county of Cheshire. The drift or adit mine was one where the access tunnel was driven into the hillside to access coal, which occurred thereabouts as a natural outcrop. Furness Clough Colliery had a vertical shaft and it was the older of the two. It probably began as a bell pit, which was a shallow shaft sunk to reach the coal. The coal was then excavated by miners who placed it in buckets that were raised to the surface by a winch, much like water being raised from a well. Bell pits get their name because the cross section of a pit resembled a bell.

Both mines were connected to the Peak Forest Canal at Furness Basin by a tramway that was probably constructed at the time that the upper level of the canal opened in 1796 or shortly afterwards. John Farey refers to this tramway in his book, ‘General View of the Agriculture and Minerals of Derbyshire’, published in 1811. He records that the tramway proceeded under the turnpike road through Furness Vale for one mile to Diglee Colliery. He also recorded that there were tipplers on the canal wharf for loading carts as well as boats with coal:

From (the canal) near Jow-hole Old Furnace (Farey's landmark refers to Gowhole, Furness Vale, which is actually on the other side of the canal), a Rail-way branch proceeds under the Turnpike-road (Buxton Road, A6), nearly SW 1m. (1 mile) to Diglee Colliery, with Tipples on the Wharf, for loading Carts as well as Boats with these Coals.

The gauge of the tramway track was 19 inches, which was similar to the gauge of other mine tramways in the Goyt Valley mining district. The coal tubs were of wooden construction with cast-iron wheels with a capacity of about 5 cwt and these were hauled by pit ponies. The chassis of such a coal tub is preserved in the New Mills Heritage Centre. On leaving the mines, the tramway generally followed a north-easterly route down the hillside to pass by the Soldier Dick Inn and then under the turnpike road (Buxton Road, A6). Just before the canal it turned northwards to arrive at Furness Basin. This basin consisted of a short arm on the offside of the canal that was practically parallel to it. This was spanned by a stone-built shed, which was still extant in 1960 but derelict. Later, this was demolished and replaced by a boat house used for the maintenance and painting of boats. When the Stockport, Disley and Whaley Bridge Railway line was constructed through Furness Vale in the 1850s it passed over the tramway without obstructing it. The railway bridge over the tramway is still extant and is now Bridge 32.

There are no records of early ownership of the mines but Tithe Apportionments and Map of 1851 shows that the landowner was John William Jodrell and the occupier of two plots, where the mines were located, was John William Boothman who also operated Furness Clough Lime Works, the location of which is uncertain. Three adjoining plots, with the same landowner, were occupied by Thomas Boothman who was a relative. It is known that Thomas Boothman was a lime merchant with premises in Manchester for the sale of Buxton lime and limestone and related products. By the early 1860s the firm was owned by a Mr West who was succeeded by Levi and Elijah Hall. Later in the 19th century it seems that the mines became rundown and Kelly’s Trade Directory of Cheshire for 1902 records that the firm was owned by the Exors of Levi & Elijah Hall and that the manager was James Collinge Hall. The company name was then given as the Furness Vale Silica & Fire Brick Co, there being no mention of any coal mining activity. In 1905 Richard Ernest Knowles (1872-1943) bought the firm and with the assistance of a skilled local miner, John James ‘Jack’ Hewitt, the mines were soon up and running again. Jack Hewitt was born in Kettleshulme in 1880 and for a while he lived in Bugsworth where he was the landlord of the Navigation Inn between 1937 and 1952.

Two seams of coal, Red Ash and White Ash, were mined and these were about 18 inches and 13 inches thick, respectively. It was often the case that seams of fireclay were embedded with the coal seams and this part of the Cheshire coalfield was no exception. The clay seam here was associated with the White Ash coal seam and it was about 5 feet thick, which was in sharp contrast with the thin coal seams. Consequently, a brickworks was founded in 1890 a short distance to the east of the coal mines and it is known that the bricks were fired in beehive kilns. Paradoxically if, indeed, both coal mines had become rundown then coal to fire the kilns would have required importing from nearby pits at Whaley Bridge and/or New Mills. The tramway was put to use carrying bricks down to the railway where a private siding, known Knowles Siding, was created. Clay was imported by rail and tramway to supplement the clay mined on site. The canal distance table for 1888 shows that Levi Hall & Son had a coal wharf at Furness Basin and it is known that the tramway connection to it was shut prior to the closure of the rest of the tramway.

A list of mines for 1908 only refers to Furness Clough Mine and records that 15 men were working below ground and one above, the manager being R E Knowles. The Ordnance Survey map for 1910 shows the fireclay works and names it as the Furness Vale Fire Clay Works but it does not show the coal mines apart from an unnamed shaft. The list of mines for 1938 records that both mines were part of the Furness Vale Colliery & Fireclay Works and that the manager was R E Knowles. This list shows that Diglee Drift Mine employed three men below ground and one above, while Furness Clough Mine employed 27 men below ground and three above.

In 1945 the firm was known as the Exors of R E Knowles, Furness Vale Colliery & Fireclay Works and the manager was J Hewitt, that is, John James ‘Jack’ Hewitt who re-opened the coal mines in 1905. In 1945 Diglee Drift Mine employed two men below ground and three above, while Furness Clough Mine employed 17 men underground and three above. Furness Clough Mine was mainly being used for the extraction of fireclay. It was not until 1963 that the mines finally closed.

On the 14 April 1944, a new company called R E Knowles Ltd was founded, which occupied the same site as the original Fireclay Works, for the manufacture of bricks, tiles and construction products in baked clay.