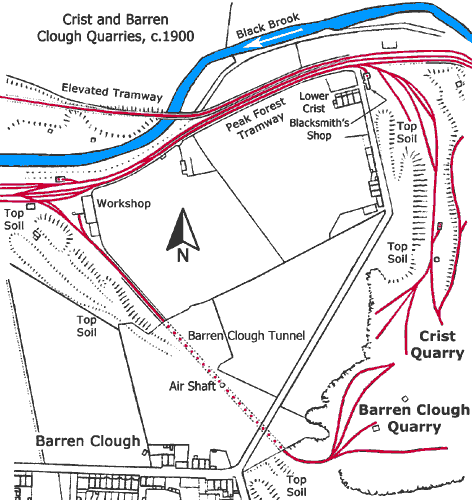

When the Peak Forest Canal Company was building the Peak Forest Tramway, between 1794 and 1796, they cut into a bed of gritstone (hard, coarse-grained siliceous sandstone) by the hamlet of Lower Crist, about 380 yards to the east of the terminus of the Peak Forest Canal at Bugsworth. They recognised that it was practicable to open a quarry there, as the stone had good non-slip properties. This bed extended south of the mainline of the tramway at Lower Crist and a branch line was made into it. The Company also discovered another deposit of the same stone adjoining the nearby hamlet of Barren Clough, which is situated between Lower Crist and the canal terminus. Consequently, they purchased land there as well but it was another 56 years before Barren Clough Quarry was opened.

Before quarrying could commence the Company had first to remove the overburden, much of which was tipped at Lower Crist on a narrow strip of land between the road from Barren Clough and the tramway branch into the quarry. Initially, this quarry was used to produce stone for bridges, wharfs, walls and buildings that were needed alongside the canal and tramway. Additionally, some of the stone sleeper blocks, upon which the tramway track was laid, would also have been made here.

As the stone had non-slip properties and never became slippery, even after considerable use, it was soon in demand for the manufacture of road setts and paving flagstones in the rapidly expanding industrial towns of the North West, especially in Manchester as it expanded eastwards through Ardwick, Beswick and Bradford. Stone from the quarry was taken by tramway to Bugsworth Basin, where it was loaded into boats. It was then carried along the Peak Forest and Ashton Canals into Manchester and from there it travelled far and wide. The non-slip property of the stone was found to be particularly advantageous for the construction of roads and pavements in hill towns and for use as stable flooring.

By 1850, the demand for stone was so great that the Manchester, Sheffield and Lincolnshire Railway Company (successor to the Peak Forest Canal Company) opened Barren Clough Quarry on adjoining land that had been purchased 56 years earlier. Both quarries produced stone up until their closure in c.1928. By the time of their closure it is understood that Crist Quarry had two working faces, each about 275 yards long and that Barren Clough Quarry also had two working faces, each about 165 yards long.

Before Barren Clough Quarry could be opened, the road between Barren Clough and the hamlet of Eccles had to be diverted. To provide access to the quarry, a tramway tunnel, about 158 yards-long, was driven under the hillside and the spoil from this and the overburden from the quarry site was deposited on the hillside to the west of the line of the tunnel and also to the south of the quarry adjoining the hamlet of Barren Clough. This became a distinctive feature of the landscape as it was in the form of long ridges that swept down the hillside.

When completed, the single-track tramway branch into Barren Clough Quarry commenced at a point 80 yards to the east of the terminus of the Peak Forest Canal. At a distance of 145 yards from the mainline, it entered the tunnel before arriving on the quarry floor. Although the tunnel was relatively short, a vertical shaft was first sunk at a distance of 76 yards from the north portal (just under half way) to enable it to be excavated from four faces at once rather than at each end. When the tunnel was completed this shaft became an airshaft, although this feature was probably unnecessary for such a short tunnel. A refuge was provided in the tunnel for workmen to stand in it whenever a gang of waggons passed by. In spite of this, it is known that a workman was killed when a gang of waggons passing through the tunnel struck him down. A cross was carved in the wall where the fatality occurred.

|

|

| North portal of Barren Clough Tramway Tunnel, c.1930. | Looking north west from inside Barren Clough Tramway Tunnel, c.1930. |

|

|

| Inside Barren Clough Tramway Tunnel, Jun 1984. | Inside Barren Clough Tramway Tunnel, Jun 1984. This view shows the refuge where workmen could stand while waggons passed by. |

The Peak Forest Canal Company was leased to the Sheffield, Ashton-under-Lyne and Manchester Railway Company on the 25 Mar 1846 and this merged with other companies to form the Manchester, Sheffield and Lincolnshire Railway Company on the 1 Jan 1847. The new Railway Company quickly recognised the value of the stone produced and it was used to build railway stations, warehouses, bridges and so on. Most famously, Grimsby Docks in Lincolnshire were built with this stone. On the 1 Aug 1897, the Company changed its name to the Great Central Railway Company and on the 1 Jan 1923 it became an integral part of the London and North Eastern Railway Company.

The Great Central Railway Company was particularly appreciative of the quality of the stone and they referred to the quarries as, 'the home of the finest freestone on the Great Central Railway'. However, times and needs were changing and its successor (the London and North Eastern Railway Company) was not so interested and the quarries closed in c.1928. The last load of gritstone to leave the quarry by way of the Peak Forest Tramway was in 1924 and this consisted of 113 tons of stone carried in about 50 waggons. This was to be the last gang of waggons to commercially use the Peak Forest Tramway. The stone was taken down to Bugsworth Basin and from there it was taken to Combs, near Chapel-en-le-Frith, where it was used to build a cottage.

When the Chapel-en-le-Frith and Whaley Bridge bypass was constructed in the 1980s, the route of the new road was placed between the Peak Forest Tramway and the north portal of Barren Clough Tunnel. Spoil from the bypass was used to fill and landscape both quarries leaving a small rock face at Crist Quarry as the only visible reminder of the former existence of these quarries. Barren Clough Tunnel survived construction of the bypass and it lies on the south side of this.

In their heyday, it is likely that both quarries were self-sufficient and this enabled the Peak Forest Canal Company and its successors to provide practically everything needed for quarrying, shaping, dressing and transportation of stone. The nature of power sources used to drive machinery is unknown and none can be easily identified on photographs. Waterpower was unavailable, so in the 1790s it is likely that work was done with the aid of horse gins and manually. Later, steam engines and then diesel engines may have been introduced but there is no evidence for this. There was an ample supply of coal from neighbouring pits and this could have been taken into the quarries by tramway. It is known that coal waggons were used on the tramway and at this juncture it is interesting to speculate whether or not waggons fitted with water tanks were ever used to deliver water to the quarries to drive steam engines. A blacksmiths' shop was built by the entrance to Crist Quarry and a workshop by the entrance to Barren Clough Quarry. Here, hand tools for use in the quarries could be made and they could also have been used for the repair of machinery and waggons.

Both quarries contained the complement of machinery that would be expected. There were cranes and derricks as well as rock-sawing and dressing machinery to enable the manufacture of road setts, paving flagstones and building stones. Additionally, there were stone-built powder houses for the storage of dynamite, which was needed whenever a rock face required blasting to obtain more stone.

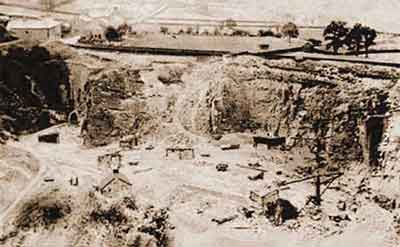

Barren Clough Quarry, early 20th century.

The south portal of Barren Clough Tunnel is on the left. The building in the foreground, centre left, has a chimney and this may be a blacksmith's shop. There is a crane on the right but the other small buildings and structures cannot be identified. It is likely that there was a powder house as well as a bothy for the workmen.

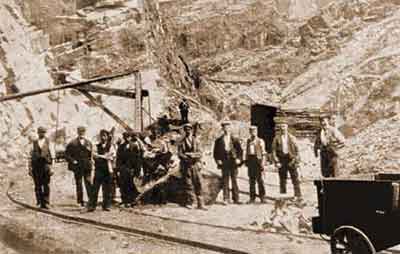

Quarrymen in Barren Clough Quarry, c.1905.

The quarrymen, left to right, are: unkn., Joshua Ashby, John Ashby, unkn. quarryman behind John Ashby, Philip Brown, unkn. quarryman behind Philip Brown, Mr Whiteman, Thomas Mellor, Mr Wilson, unkn. and Daniel Haughton. The quarryman in the centre background is John Pearson.

Up to 80 quarrymen worked in Barren Clough and Crist Quarries, including skilled stone workers who could cut and dress stone for specific purposes, and they worked a 12-hour day.

As a result of blasting and stone removal, the quarry faces were constantly changing and consequently the layout of the tramway network on the quarry floors would necessitate being changed as well. For this reason, it is possible that the track in both quarries was laid on wooden sleepers, rather than on stone sleeper blocks in the manner of the mainline of the tramway. Stone from both quarries travelled the short distance down to Bugsworth Basin where it was loaded into boats at the gritstone wharf on the south side of the Upper Basin. To facilitate this, a cantilever jib crane was provided on this wharf. At one stage there was a second crane on this wharf, adjoining the lime shed, but little is known about it.

Archive photographs show dressed stone on the gritstone wharf awaiting loading into boats but, additionally, it seems reasonable to assume that some stone was brought down in its raw condition. The latter could either have been loaded directly into boats or it could have been processed at the limestone crusher house adjacent to the Lower Basin. While the limestone crusher house was purpose built to crush limestone, there was no reason why it could not have been used to crush gritstone. It is understood that by the early 1920s it was being used solely to crush gritstone, much of which was waste recovered from around the quarry floors.

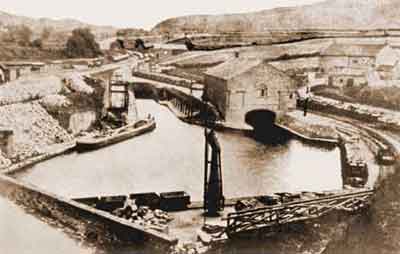

The Upper Basin at Bugsworth, 1910.

The gritstone wharf is on the right and in the centre foreground is the cantilever jib crane used to load stone into boats. On the wharf, in front of the lime shed, a neat stack of gritstone is waiting to be loaded into boats. Gangs of waggons stand alongside the lime shed, all loaded with dressed gritstone from Barren Clough Quarry.

Crist and Barren Clough Quarries were not the only ones to supply gritstone to Bugsworth Basin. There was a small quarry situated behind the Primitive Methodist Chapel in Bugsworth and access to this was gained by means of a short tramway tunnel that led directly onto the quarry floor. This tunnel is still extant adjoining the chapel.